Essential Equipment In Custom Kraft Boxes Packaging

Custom kraft boxes have gained popularity in contemporary packaging, where they have become a way of life and are also versatile, durable and beautiful. Regardless of the use of the box, be it retail, e-commerce or a present, the boxes will add to a product presentation with a practical delivery and display solution. The articles and methods provide solutions to businesses to bring their packaging to a new level by using tools and methods designed to cut, finish, and design.

Since Kraft boxes with h windows are smaller than Kraft boxes, knowing how to use the right tools is a sure way to achieve efficiency, quality and personalization. The UK competitive custom boxes market requires the use of appropriate equipment and practices to enable the brands to come up with attractive, functional and memorable packaging that appeals to consumers.

Tilting And Scoring Machines

The quality of Brown kraft boxes requires precision cutting and scoring tools to create quality boxes. All the boxes can be professionally made as these machines permit precise folds, neat edges, and regular appearances. In the case of enterprises that manufacture brown kraft boxes or black kraft boxes, the accuracy of tools reduces wastage of materials and increases the production rate. With or without the fancy die-cut machines in place of manual scoring boards, cutting and scoring devices form the basis of custom packaging that appears polished and long-lasting. The correct equipment is used to make all boxes structurally sound and accommodate various design and branding needs.

Printing Technology Alternatives

The printer tools used are also of high quality to enable kraft boxes with a window to be visually appealing. Digital printing, flexography and offset printing are some methods through which brands can use logos, patterns and colourful printing on the kraft surfaces. In a custom kraft box, printing will provide an aspect of customization, which will win some level of attention and brand awareness. The use of appropriate ink, finish, and printing technology is the way to make sure that colours are consistent and designs are sharp. The high-end printing equipment can also be combined with specialty finishes, such as foil stamping or spot UV, to make a packaging stand out in a saturated Kraft boxes UK market.

Embossing and Debossing Equipment

The tools of embossing and debossing make custom kraft boxes have a touchy and quality feel. The businesses can bring out the logo or pattern, or information about the products, in a beautiful way by designing raised or recessed patterns. They are also effective on small kraft boxes containing cosmetics, accessories or gift products, which adds to the unboxing experience. The correct embossing equipment can also be used to provide precision, repeatability and clean impressions without destroying the material. By including these tools, the brands can portray the message of sophistication and attention to detail in the packaging, making it engaging and not functional only.

Window And Cut-Out Tools

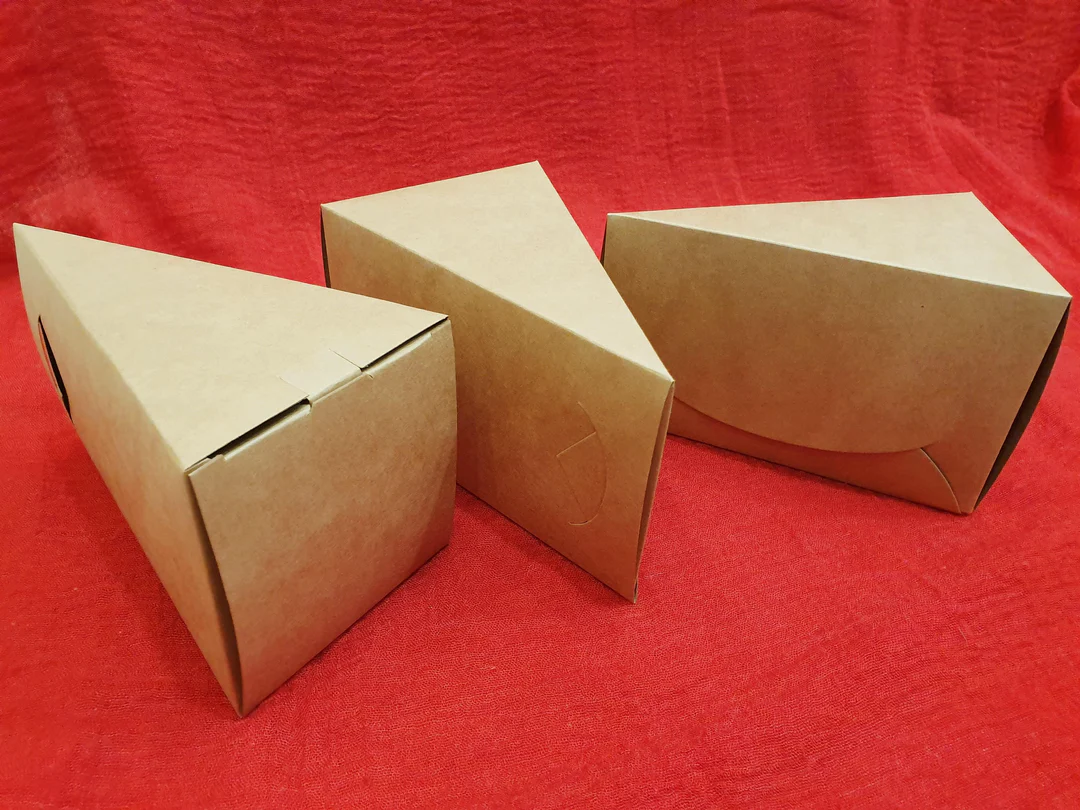

In the case of products that are good to be seen through, Kraft boxes with windows need the use of a sharp razor to cut the boxes to make transparent areas. These windows are used to display the product within them, making them structurally sound. Die-cut machines or laser cutters are clean and precise enough and support complex designs or custom sizes. The correct application of window and cut-out tools will improve customer trust since the product will be visible, giving packaging the interactivity it deserves. This approach is particularly useful when dealing with high-value products, gifts and displaying in retail outlets, as it is functional and attractive.

Adhesive And Assembly Machinery

Production of custom kraft boxes is efficient because it is made by efficient assembly tools that save time and preserve quality. The boxes are made through hot glue guns, taping dispensers and automated folding machines. When it comes to black kraft boxes or brown kraft boxes, it is best to use the appropriate adhesives to eliminate gaps, warping or misalignment. Scalability is gained using assembly equipment, which enables businesses to use it when they have to deal with large orders without compromising on precision. The appropriate equipment would ensure that every box is shippable or displayable in stores with a professional look that would be well-received by the brand.

Finishing And Coating Tools

Tools are used to provide the durability and beauty of custom kraft boxes. Varnishing, lamination, and UV coating secure the printed designs against wear and are a good addition to a luxurious appearance. It can be applied to small kraft boxes or brown kraft boxes and enhance the shelf image and perception by customers. Special tools offer uniform coverage, and they do not peel or leave uneven finishes. The use of finishing methods improves the quality of the packaging, branding, and customer experience so that every box creates a powerful impression, starting with the first look and continuing through unboxing.

Handling Solutions and Storage

Custom kraft boxes are well stored and handled with proper tools to ensure a good quality is maintained. Shelving, bins and protective covers do exclude deformation damage, particularly with large pillow boxes or custom kraft boxes with windows. Effective handling systems improve the process of work within the warehouse or production facility, decreasing waste and improving productivity. In the case of businesses in the custom boxes market UK, organized storage solutions will help to maintain the perfect condition of the boxes before shipping, so as to continue to emphasize brand and customer satisfaction.

Quality Control And Inspection

Manufacturing of tailor-made kraft boxes requires quality control tools. Apart from size, colour, and structural specification, measuring devices, inspection cameras and sample testing are used to make sure that each box is within the size, colour and structural requirements. In small kraft boxes or specialty designs, defects are avoided with regular inspection and consequently, high standards are ensured. A structured QC operation assists companies to spot the problems at an early stage, minimize returns and preserve customer confidence. Quality consistency reinforces the brand image among the existing competitive Kraft boxes UK market and ensures that every custom presentation pillow box produces the aesthetic and functional experience that the target audience desires.

Conclusion

Custom kraft boxes are not just another packaging but a marketing and practical tool that depends on the correct equipment. Precision cutting, printing, embossing, assembly, and finish tools used on kraft boxes with windows, black kraft boxes, small kraft boxes, etc, improve the quality of packaging.

Effective storage, handling and quality control will ensure that the boxes are of brand standards and also increase customer experience. In the case of businesses in the UK, these tools should be considered determinants of production that enhance aesthetics and efficiency. It is with these fundamentals that brands can design packaging that is convenient, attractive and distinctly memorable.