BIM Modeling Strategies for Large-Scale Projects

Large-scale projects are beasts — many stakeholders, long schedules, and a higher risk that a small mistake becomes an expensive problem. If you want the job to run smoother, you need more than good people: you need a repeatable approach. That’s where BIM Modeling Services matter. They provide the framework for coordination, decision-making, and traceable data. Pair that with strong Architectural BIM Modeling practices, and you move from firefighting to planning.

Start with clear objectives, not software

Before anyone opens a Revit file, ask what success looks like. Are you optimising schedule, reducing lifecycle cost, improving sustainability, or all of the above? Set two or three measurable goals and then design workflows around them. This keeps the team focused and turns the model into a decision tool, not a file repository.

Governance: who does what and when

Large projects fail fast without governance. Simple, enforceable rules work best.

Key governance habits

-

Appoint a BIM Modeling Services manager who publishes the federated model and enforces version control.

-

Create a responsibility matrix that names who updates what and who resolves clashes.

-

Agree on common naming and file conventions at kickoff to avoid confusion later.

When responsibilities are visible, small problems don’t slip through the cracks.

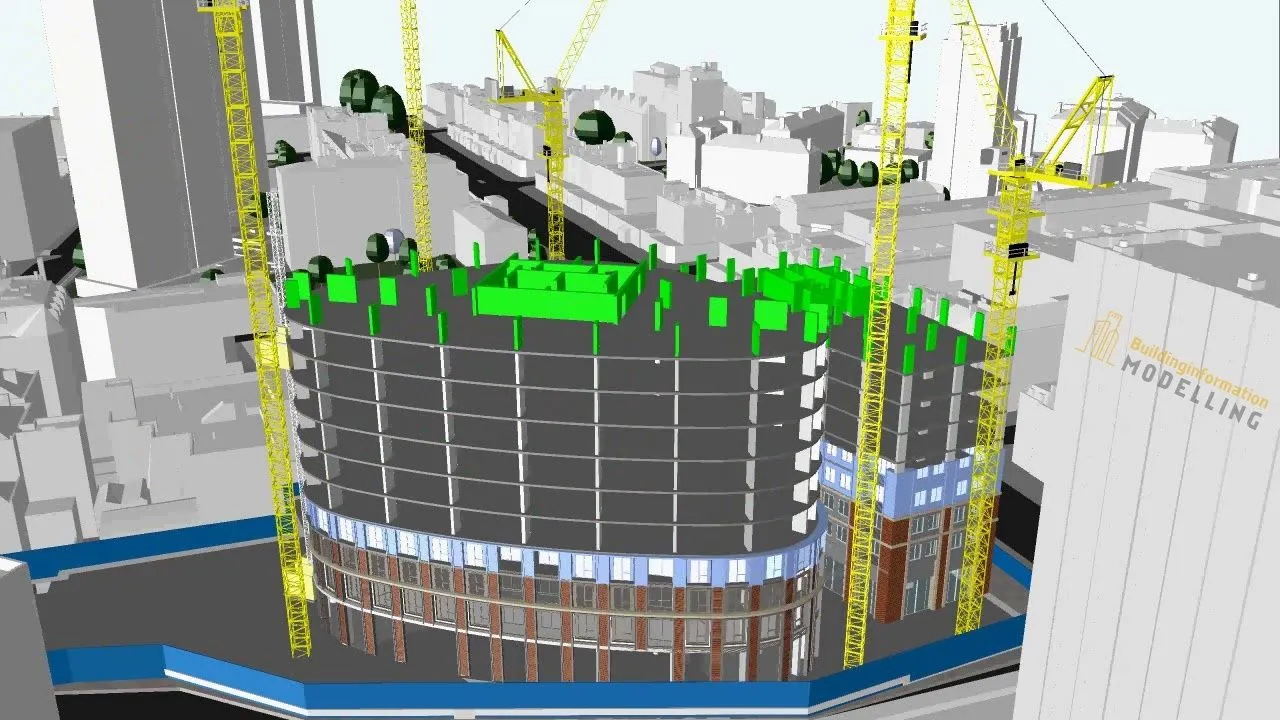

Federated models and practical coordination

For large projects, keep discipline models separate, then federate them for coordination. This prevents the single master file from getting bloated or corrupted.

-

Structural, MEP, and Architectural BIM Modeling teams keep focused files but publish into a central coordination model.

-

Run scheduled clash detection and keep reports triaged by impact, not count.

-

Use model viewers for quick, shared walkthroughs instead of emailing huge files.

Federation helps teams keep their workflows while still seeing the whole picture.

Phased validation: staged checks that save time

Don’t wait until the documentation to check everything. Do staged reviews:

-

Concept/Schematic: validate massing, key grids, and core clearances.

-

Design Development: run main clashes and check major routes for MEP.

-

Pre-construction: final clash resolution and shop-drawing readiness.

Tackling issues progressively prevents the avalanche of fixes at the end.

Integrate schedule and cost: 4D and 5D thinking

A model is far more valuable when it talks to time and money.

-

Link model geometry to schedule elements to simulate erection sequences and detect logistics conflicts.

-

Connect quantity outputs to cost models so owners see the financial impact of design choices.

-

Use simple scenario runs to test “what if” changes quickly.

This integration turns theoretical coordination into operational reality.

Standardisation: templates, families and libraries

Large projects scale when teams reuse proven components.

-

Build parametric families and standard detail libraries that match fabrication limits.

-

Predefine tolerances and transport sizes so off-site fabrication is realistic.

-

Maintain a living library and freeze versions when projects enter documentation.

Standards speed delivery and reduce the number of bespoke problems that crop up on site.

Communication rituals that keep things human

Technology helps, but people decide. Keep meetings short, visual, and action-oriented.

-

Weekly 30–45 minute coordination calls focused on blockers and decisions.

-

Publish a short decision log after each meeting so changes are traceable.

-

Walk the model with trade leads before fabrication starts — practical eyes catch issues software misses.

These rituals embed BIM into the team’s daily habits rather than treating it as an “extra.”

Fabrication and prefabrication alignment

For big jobs, prefabrication reduces risk — but only if the model is usable for fabricators.

-

Run early prefabrication checks and involve fabricators in model reviews.

-

Verify connection details and tolerances against manufacturing limits.

-

Use model geometry to generate accurate shop drawings and avoid late redesigns.

Involving builders early turns theoretical efficiency into on-site speed.

Handover and lifecycle value

The project doesn’t end at practical completion. The model should be a tool for operations.

-

Attach asset metadata—serial numbers, maintenance intervals, warranty info—so facility teams get value fast.

-

Deliver a tidy handover model and a short guide to asset queries and updates.

-

Keep a plan for periodic model audits so the digital record stays useful over time.

A clean handover converts short-term effort into long-term savings.

Conclusion

Large-scale projects reward discipline more than heroics. If you combine clear objectives, strong governance, federated models, staged validation, and human-centered communication, BIM Modeling Services will help you reduce surprises and speed delivery. Architectural BIM Modeling keeps design intent visible so the building is both practical and purposeful. Start small, formalize the rules, and treat the model as your working plan — not just a deliverable.

Want more knowledge about our BIM Modeling Services? Read our blog now: CAD vs BIM: What Is the Difference Between CAD and BIM | Which One Do You Need for Your Project?

FAQs

How often should clash detection run on a large project?

Run clash detection at each major design milestone and weekly during pre-construction; frequency rises as you approach fabrication.

Who should own the federated model?

A BIM manager typically publishes the federated model; discipline leads own their individual files and resolve assigned clashes.

What’s the best way to involve fabricators early?

Schedule targeted pre-fab reviews with fabricators using model extracts; focus on connections, tolerances, and transport constraints.

How do you keep the handover model useful for operations?

Attach asset metadata, provide a short handover guide, and schedule periodic audits to keep as-built records current.